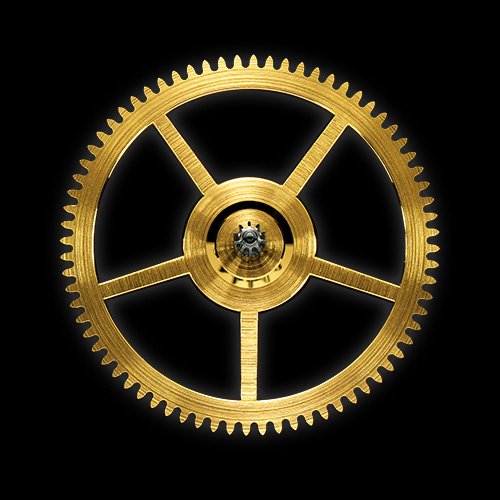

The wheel trains are parts of the watch mechanism and are subject to very strict decorative criteria, to ensure all machining marks are eliminated. The numerous operations needed to ensure a flawless finish on the wheel trains require many hours of meticulous work.

Requirements for the wheels of the going train

1. They must be chamfered above and below.

2. For wheels of up to 0.15 [mm] thick, a single chamfer is allowed.

3. They must have polished sinks.

4. For wheels less than 0.15 [mm] thick, a single sink is allowed.

5. The shape and position of the sink are at the discretion of the applicant, provided the sink is polished.

6. The crossing, hub and rim of the wheels must be chamfered.

7. The functional parts of the pivot-shanks and pivots, including their faces, must be burnished. The other parts must be finished so as to eliminate all machining marks. The ends of the pivots must be polished.

8. The pinion faces must be finished so as to remove all machining marks, without rounding off their edges or flattening out burrs. Polishing, grinding or any other finishing operations are acceptable provided they do not contravene the foregoing requirements.

9. The pinion leaves must be polished without modifying the functional part of their tips.

Requirements for wheels and gears that are not in the going train

1. They must be finished so as to remove all machining marks.

2. Wheels with crossings must be finished in the same way as the going-train wheels.

3. The ratchet-wheel and the crown-wheel must be decorated so as to remove all machining marks.

4. The ratchet-wheel and the crown-wheel must have chamfered and polished teeth, if thick enough.

Jewels

Jewels are used to prevent wear due to the constant friction on the contact points of bearings. The Poinçon de Genève specifies that jewels on the bridge side must be semi-brilliant with polished sinks.